The right enclosure is more than a functional decision—it’s the first impression a device makes. A well-designed enclosure enhances usability, reinforces branding, and ensures durability. Fortunately, finding the ideal solution doesn’t have to be frustrating or time-consuming.

Engineers and manufacturers need solutions that offer proven performance and a seamless customization process—without unnecessary complexity. While fully custom enclosures can be costly and slow to develop, prefabricated enclosures with customization options offer a practical, efficient alternative.

Product Invention: Why Enclosures Matter

Choosing an enclosure isn’t just a technical decision—it’s a strategic one that affects everything from manufacturing to how a product is perceived by the end user.

Here’s what the right enclosure brings to a project:

- Protection – Electronic instrument enclosures shield sensitive electronics from dust, moisture, physical impacts, and electromagnetic interference (EMI).

- Compliance – Enclosures ensure that your products meet industry standards for safety, durability, and electronic performance.

- Efficiency – Prefabricated enclosures greatly simplify assembly and maintenance, which reduces production time and labor costs.

- Branding – Customizing your enclosure gives it your brand’s personality with finishes and logos, creating a device that’s uniquely yours.

- Affordability – Prefabricated enclosures avoid the expense and complexity of fully custom enclosures by modifying proven designs, which reduces development costs and minimizes supply chain bottlenecks.

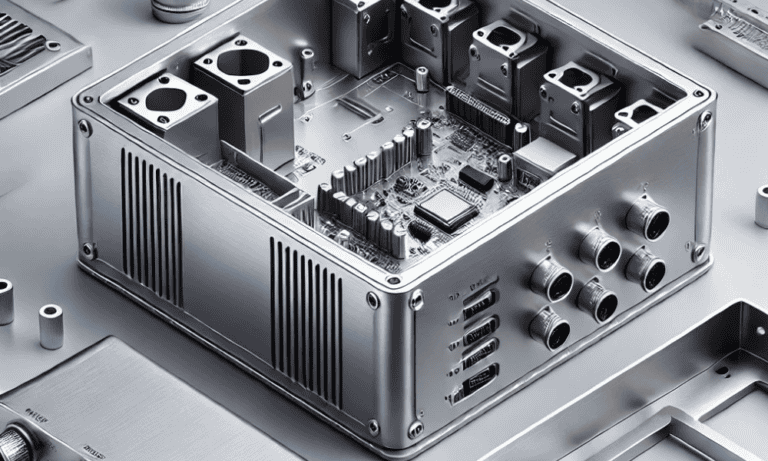

Enclosure Examples

Instead of starting from scratch, prefabricated designs provide a reliable foundation that can be tailored to fit specific project needs. For example, GrayBox and MicroPak – two versatile options from Lansing Instrument Corp – demonstrate how pre-engineered enclosures can be customized for performance, protection, and ease of integration.

GrayBox Enclosures

- Ideal for: Rack-mounted and free-standing applications.

- Strengths: Durable all-metal construction with a rugged extruded frame, removable top and bottom covers, and versatility with a large array of dimensions and configuration options

- Best for: Industrial control systems, laboratory equipment, and medical devices.

MicroPak Enclosures

- Ideal for: Compact, portable, or handheld applications.

- Strengths: High-quality extruded aluminum construction with multiple size options, customizable end configurations, and versatile mounting for printed circuit boards.

- Best for: Data acquisition units (sensors), portable electronics, and IoT devices.

These enclosures are prime examples of adaptable designs, balancing affordability and performance while eliminating the hassle of modifying enclosures that weren’t designed for your needs.

How to Configure an Enclosure: A Simple, Hassle-Free Process

Here are four simple steps (and a few sub-steps) to ensure you achieve a perfect fit.

Step 1: Define Your Project Requirements

Before selecting an enclosure, outline your key needs:

- Size: Determine width, height, and depth constraints.

- Component Layout: Plan for printed circuit board (PCB) mounting, connectors, and airflow needs.

- Environmental Factors: Consider moisture resistance, EMI shielding, and durability.

- Aesthetic Preferences: Choose colors, branding, and finishes.

Step 2: Select an Enclosure

Choose the right enclosure based on your project’s needs:

- Larger, modular enclosures for industrial applications – GrayBox.

- Compact and portable solutions – MicroPak.

Step 3: Customize Your Enclosure

Customization serves two key purposes: functionality and branding. A properly tailored enclosure ensures that components fit securely, ports and buttons are easily accessible, and the device operates as intended. At the same time, custom finishes, colors, and logos create a polished look that reinforces brand identity and makes a strong impression.

1. Size Adjustments

- GrayBox: Designs offer flexible height options of 1u, 2u, and 3u, making choosing a depth to fit your specifications simpler.

- MicroPak: Length is adjustable, while the width and height are fixed to ensure a consistent, pleasing design.

2. Machining for Ports and Mounting

- Custom-cut openings for connectors, buttons, and ventilation, ensuring a perfect fit for your components and airflow needs.

- Self-clinching inserts for securely mounting PCBs, brackets, or other hardware without the need for screws or extra tools.

3. Graphics and Branding

- Custom silkscreening for logos, text, and operational markings, ensuring clear and professional identification.

- A variety of color options to match branding needs and enhance product presentation.

4. Surface Finish Options

- Choose from standard and custom finishes designed to enhance durability and visual appeal.

- Conductive coatings are available for EMI shielding and compliance.

- Protective anodized finishes provide superior corrosion and abrasion resistance, while limiting electrical conductivity where necessary.

5. Electrical Shielding for Regulatory Compliance

- Conductive coatings help minimize electromagnetic interference (EMI), ensuring compliance with regulatory standards.

- Additional grounding fasteners to enhance electrical stability based on the specific needs of the project.

Step 4: Prototype and Testing

- Order a prototype to verify fit, function, and durability.

- Perform environmental testing to ensure compliance.

Step 5: Finalize and Begin Production

- Confirm design specs.

- Enjoy an easy and stress-free ordering process with expert support.

Lansing Makes Creating Custom Electronic Enclosures Simple

Choosing and customizing an enclosure doesn’t have to be complicated or costly. By selecting a design that balances performance, affordability, and easy configuration, you can seamlessly integrate it into your product development—without unexpected hurdles or expenses.

Lansing Instrument Corp simplifies the process of selecting and customizing enclosures further, offering a family of prefabricated enclosures and a streamlined tailoring process that ensures your enclosure meets both technical and aesthetic requirements without the high costs and delays of fully custom designs. Ready to configure an enclosure that enhances your product’s performance and brand identity? Contact Lansing to explore how a modular GrayBox or compact MicroPak enclosure can bring your project to life.