When planning an electronic project, whether for industrial, commercial, or personal use, selecting an electronic enclosure is a critical, often overlooked, decision that can mean the difference between success and failure. The right enclosure does more than house your components; it protects them from environmental factors, enhances durability, and even impacts the overall functionality of your design. Conversely, opting for the wrong enclosure can lead to inefficiencies, heightened risks, and unnecessary costs.

With various options available on the market, understanding the nuances of electronic enclosures can make all the difference when selecting one for your project. Lansing Instrument Corp understands this importance and has compiled several considerations for choosing an enclosure design.

The Importance of Choosing the Right Electronic Enclosure

Electronic enclosures serve as the protective barrier between your device and the outside world. Selecting an appropriate enclosure is not just about aesthetics or housing your components; it’s about ensuring your project operates reliably and efficiently over its lifespan.

Enclosures safeguard your components from environmental factors such as dust, moisture, extreme temperatures, and physical impacts. They can also help ensure user safety by preventing accidental contact with electrical components.

Conversely, selecting the wrong enclosure can lead to component failure, higher maintenance costs, or even safety hazards – resulting in costly mistakes. For instance, an enclosure that lacks proper ventilation can lead to overheating, while insufficient protection against electromagnetic interference can disrupt your device’s performance. Therefore, selecting the right enclosure extends your project’s lifespan and ensures optimal functionality and compliance with safety standards, setting your project up for long-term success.

Considerations When Selecting an Enclosure

When evaluating electronic enclosures, several factors should guide your decision:

Material

Will your enclosure be exposed to harsh conditions like extreme temperatures, moisture, or chemicals? If so, the right material plays a crucial role in durability and resistance.

Enclosure materials fall into two common categories: plastic and metal enclosures. Metal enclosures offer superior strength, thermal conductivity, and EMI shielding, making them ideal for demanding applications. Plastic enclosures, on the other hand, are lightweight, cost-effective, and resistant to corrosion.

Environment

Assess the conditions where your device will operate. Will it be used indoors or outdoors? Is it exposed to extreme temperatures, moisture, or corrosive substances?

The environment dictates the level of protection your enclosure needs to provide. For example, if your project will be exposed to dust or water, look for enclosures rated for ingress protection (IP).

Thermal Management

If your components generate significant heat, cooling and ventilation are necessary. Heat management is critical, especially for high-power devices, so you should consider an enclosure with built-in ventilation, heat sinks, or fan mounts.

Compliance

Depending on your industry, your enclosure may need to meet specific safety or performance standards, such as NEMA or IP ratings.

Size and Fit

The enclosure must comfortably fit your components with enough room for proper ventilation and potential future modifications. Consider space for connectors, wiring, and cooling mechanisms.

Mounting Style

Determine whether your enclosure needs to be freestanding, wall-mounted, or rack-mounted as this will impact the design and mounting accessories.

Configurability – Customization and Accessibility

The ability to customize an enclosure can be significant, whether customizing for performance and accessibility, such as cutouts for connectors and displays, or including options for easy access to internal components for maintenance or upgrades. Additionally, consider any specific branding or aesthetics you want to be part of your enclosure such as colors, finishes, images, and more.

Cost and Lead Time

Balance your budget and time constraints with the required features. Remember that investing in a quality enclosure can save you money in the long run by protecting your components effectively.

Common Types of Electronic Enclosures

Electronic enclosures come in various materials and configurations, each suited to different applications. Here’s a breakdown of the most common types:

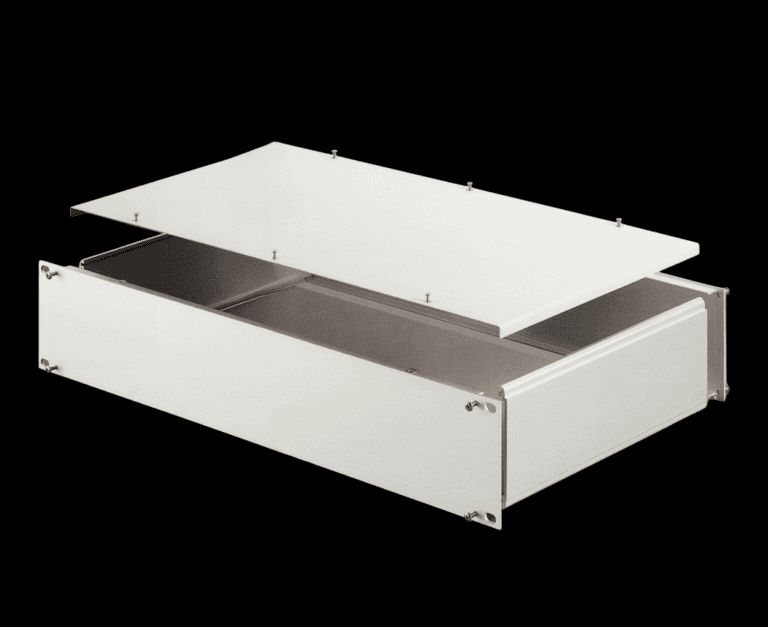

Metal Enclosures: Known for their strength, durability, and EMI shielding properties, metal enclosures are perfect for industrial, automotive, and outdoor applications. Materials like aluminum and stainless steel provide excellent corrosion resistance and thermal conductivity.

Aluminum Enclosures:

- Lightweight yet durable

- Excellent heat dissipation

- Natural EMI shielding

- Corrosion-resistant (especially when treated)

Stainless Steel Enclosures:

- Highly durable and fire-resistant

- Suitable for harsh environments

- Excellent for outdoor and wet applications

- More expensive than other options

Plastic Enclosures: Lightweight, cost-effective, and non-conductive, plastic enclosures are ideal for indoor applications where protection from moisture or extreme temperatures is not a primary concern. Common applications include consumer electronics, handheld devices, and medical equipment.

Polycarbonate Enclosures:

- Lightweight and cost-effective

- Excellent impact resistance

- Versatile for indoor and outdoor use

- Good insulation properties

ABS Enclosures:

- Affordable and lightweight

- Suitable for indoor applications

- Easy to customize and mold

Achieve Long-term Success Driven by Informed Decisions

Choosing the right electronic enclosure is a critical step in ensuring the success and longevity of your project. By investing time upfront in selecting the right electronic enclosure, you’re not just protecting your components – you’re investing in the overall success and reliability of your project.

Remember that the perfect enclosure balances protection, functionality, configurability, and value.

Combine Quality and Value with Lansing’s Proven Enclosure Designs

Selecting an enclosure doesn’t have to be overwhelming. Lansing’s electronic enclosures are designed to provide the right combination of durability, reliability, performance, and customization. With a wide variety of materials, sizes, and mounting options, Lansing can ensure that you’ll find the ideal fit for your project.

Whether you’re designing a new system or upgrading an existing one, Lansing is here to help ensure your project is equipped with the best protection and functionality available. Visit Lansing’s website today to shop now or contact us for personalized assistance.